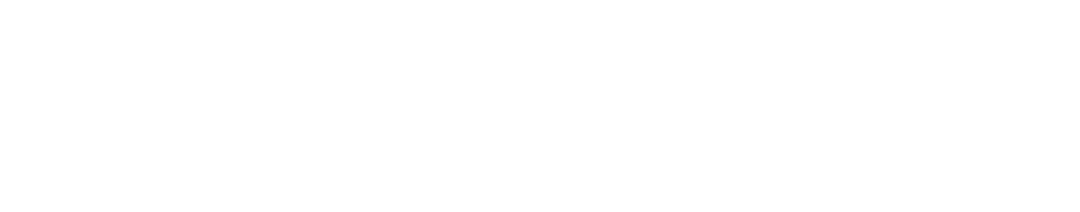

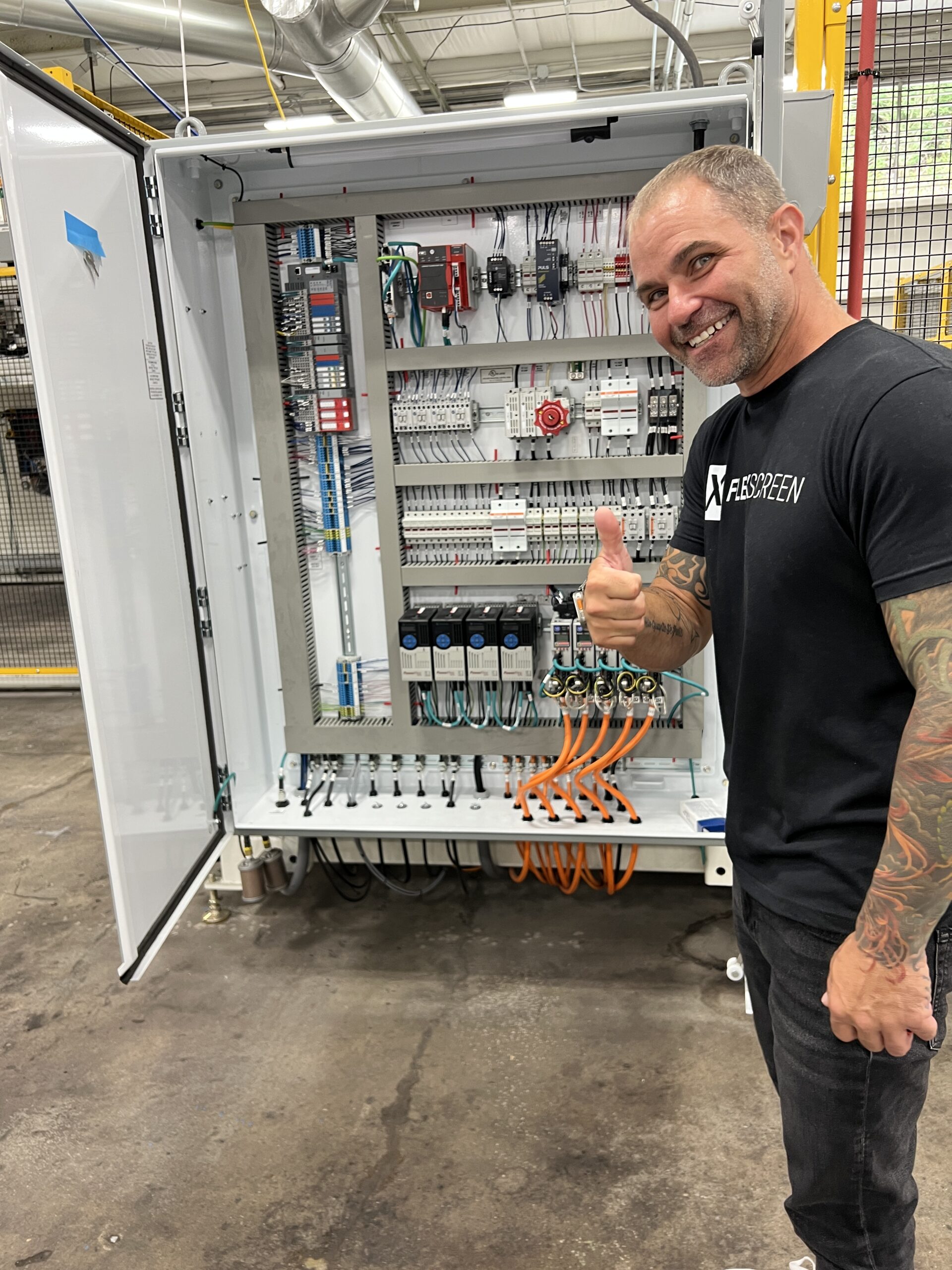

ENTREPRENEUR INVENTOR

SPEAKER

AS SEEN ON:

"I'm a life-long innovator, entrepreneur, and problem solver who turned my cutting-edge invention, FlexScreen - the world's first and only flexible window screen - into a thriving multi-million-dollar company. I want to help you do the same."

MY PODCASTS

LATEST ON THE BLOG:

Let’s Wrap It Up

If you're a Spotify music listener, you know about their popular year-end wrap-up that breaks down and analyzes your listening habits over the past year ...

Read More Shake That Can

Growing up, my grandfather was a superhero to me. I would spend weekends and summers helping him and learning the lessons that can only be ...

Read More The Biggest Flex Is Being Flexible

"Progress is impossible without change, and those who cannot change their minds cannot change anything." - George Bernard Shaw. The official Merriam-Webster dictionary lists change as a ...

Read More Put Me In, Coach

According to a study published in the Harvard Business Review, 8.9% of employees feel engaged with tough bosses, 6.7% feel engaged with nice bosses, but 68% ...

Read More The Question That Saved My Business

Dissent. Disagreement. Division. Divisiveness. Dog and pony show. Dereliction of Duty. Demonization. (Why do they all start with D?) Raise your hand if you're sick ...

Read More Humble Confidence: How Do You Do That?

"Pitch me outside, and I will hit .400. Pitch me inside, and you will not find the ball. -Roberto Clemente Roberto Clemente, who played 18 ...

Read More